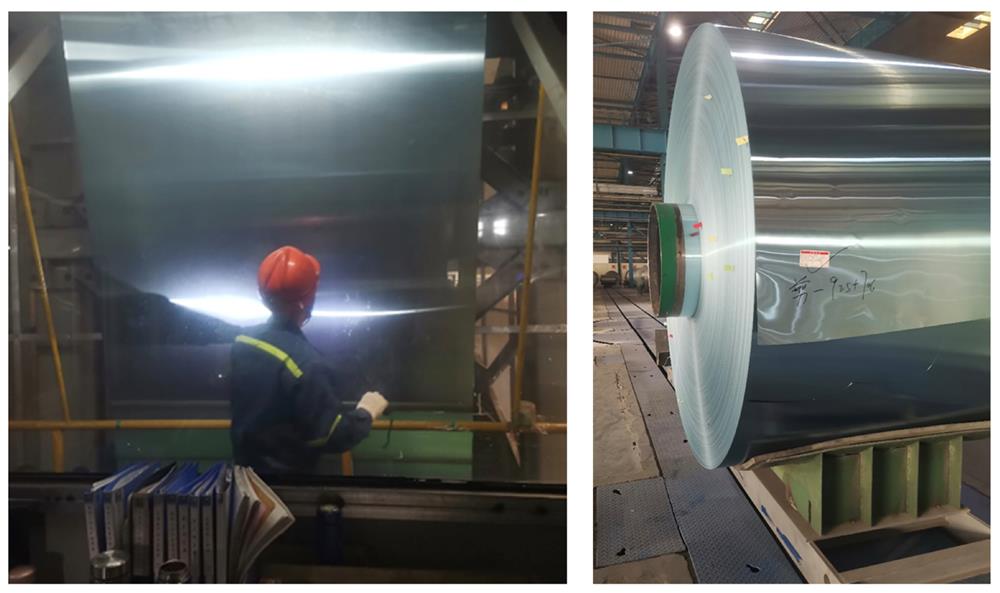

During the industrial production process, the surface of metal sheet products may suffer from damage caused by processing equipment or adverse industrial environments, resulting in certain surface quality problems, such as scratches, holes, and spots. These surface defects not only directly affect the appearance of products, but also have an impact on the mechanical performance, usability, and yield rate of finished products. Taking industrial product aluminum foil as an example, it is mainly used as a radiator for air conditioners. Its surface has a coating layer that not only needs to have hydrophilicity, but also undergoes acid and alkali resistance testing to ensure its anti-corrosion function. In the production process, defects such as missing coating and scratches may occur due to various links and equipment, resulting in the failure to achieve the normal product function and usability. Currently, product quality inspection is manually completed, but the manual measurement and judgment will generate errors and mistakes due to fatigue, subjective differences, etc. Traditional manual visual inspection methods have disadvantages such as low detection rate, poor real-time performance, low detection confidence, and poor environmental adaptability.

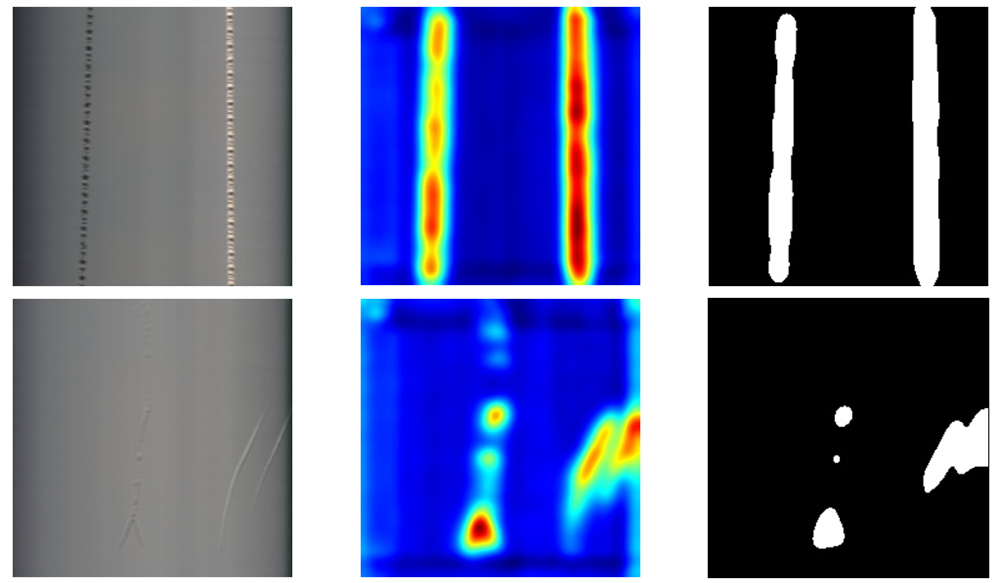

This intelligent defect detection project is based on computer vision and deep learning technology, combined with high-precision industrial cameras, aimed at intelligent detection of defects in industrial fields. The project can automatically judge and label various types of defects, including missing coatings, scratches, foreign objects, etc., by analyzing and recognizing images taken during equipment operation in real-time, thereby improving the efficiency and accuracy of production line inspection. The project has accumulated a large amount of image data and continuously optimized the algorithm to achieve high detection accuracy and stability, with the false detection rate reaching 0 and the missed detection rate reduced to less than 20%.